WORKHOLDING

WHAT IS WORKHOLDING?

Workholding refers to a device that secures a workpiece while machining. It can be as simple as clamp or as sophisticated as crankshaft pin milling chuck. It is a critical part on a machining center and provides precise position and orientation for the workpiece.

At present there many workholding options when it comes to machining a part. Workholding largely depends on the part; light, heavy, blanks, barstock, thin-walled or irregular shapes. The device should be able to secure the part without damaging it.

HOW TO SELECT THE RIGHT WORKHLODING?

Furthermore, it is important to select the right device as it can save time, increase production and ensure safety. Select the workholding depending upon the material being cut, tolerance requirements, shape, weight, thickness and the batch size. Often, customised solutions are required for irregular work-pieces and thin-wall components. Besides, modern manufacturing demands high accuracy and repeatability. Experienced engineers at GMT will help you choose the most efficient workholding and optimise productivity.

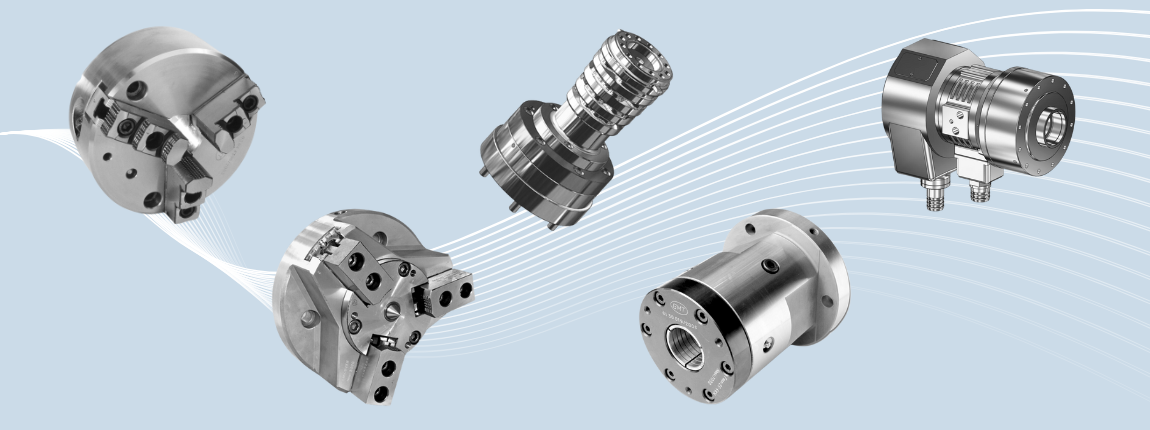

GMT WORKHOLDING RANGE

Besides standard CNC lathe chucks, GMT has a wide range of workholding products from manual chucks to custom built chucks that can provide solutions to your work-holding problems.

GMT range of manual chucks are sturdy and delivers high gripping force. The conventional bevel gear and scroll have been replaced by a worm & worm wheel to operate the jaws. Consequently, this mechanism gives the chuck an amazingly high mechanical advantage and gripping power.

GMT Power Operated High Speed Chucks rotates at high speeds on CNC lathes. The compact construction of the GMT Power Chucks offer further advantage of less weight and low inertia which have positive influence on the dynamic effect of CNC machine spindle.

GMT makes custom built chucking system for special applications. These specially designed Power Operated Chucks have gained the trust of GMT customers due to GMT’s high technical standards.

GMT manufactures a wide range of cylinders from conventional pneumatic cylinders to highly sophisticated extra large 350 mm diameter hydraulic cylinders.

Finally, the EMA’s use is on rotating work spindles where there are restrictions on the use of pneumatic or hydraulic rotating cylinders for the actuation of power chucks, expanding mandrels, collets etc.

Finally, please visit us at https://gmtmachinetools.blogspot.com– a new blog dedicated to all GMT customers…interact with our technical experts.